Posiadamy następujące maszyny drukujące:

- SOMA OPTIMA

- SOMA MIDI

- SOMA MIDI II

- BOBST

- Cerutti - ROTO

- W&H - ROTO

Nasze atuty to:

- wysoka i stabilna jakość oraz perfekcyjne wybarwienie nadruku;

- doskonała precyzja registrów.

Produkujemy opakowania w strukturach:

- monofolie;

- duplex;

- triplex.

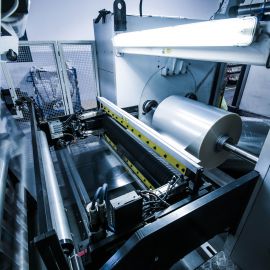

Posiadamy maszyny laminujące:

- Nordmecanica Simplex

- Comexi - Nexus Dual

Nexus Dual będąca najnowocześniejszą konstrukcją firmy Comexi, umożliwia laminację w systemach kleju bezrozpuszczalnikowego i rozpuszczalnikowego oraz aplikację cold sealu w registrze.

Instalacja mieszalni farb INK Maker GT18 oraz wdrożenie systemu recepturowania kolorów, opartego na Color Management System, umożliwia nam wytwarzanie farb drukarskich we własnym zakresie, z komponentów czołowych światowych producentów.

Dział konfekcjonowania stanowi pięć maszyn do cięcia:

- JURMET 1000

- JURMET 1300K

- Soma PLUTO II 1300

- Soma PLUTO II 1100

- Miller

Ogromną wartością naszej firmy jest własne studio DTP, w którym obróbką projektów zajmują się wyspecjalizowani graficy z wieloletnim doświadczeniem.

Posiadamy naświetlarkę laserową CTP model CDI Spark 4835 sterowaną, ripem Nexuss.