RESEARCH AND DEVELOPMENT CENTRE

The task of the Research and Development Centre is to conduct research related to the development of innovative production technologies and the use of packaging materials in both the food sector and other industries.

The laboratory and office space of the Centre has been expanded (by 900 m2) and a 1500 m2 hall has been made available for development works and industrial testing. The Centre has been equipped with modern machinery required for the entire packaging production process (printing, lamination, cutting and forming), as well as research apparatus, including advanced laboratory and measurement equipment, which allows us to:

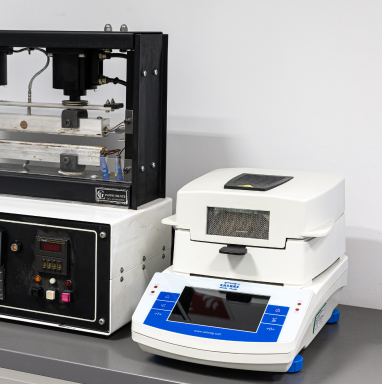

- Test oxygen permeability (O2TR) and water vapour permeability (WVTR);

- Analyse the structure of packaging (Raman spectrometer)

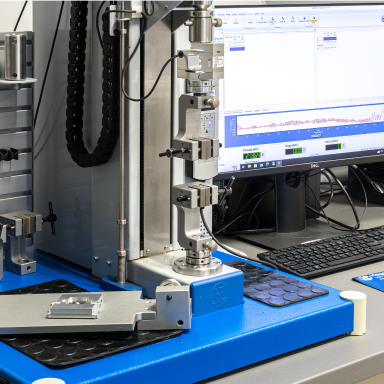

- Test the strength of heat-sealed joints (Hot Tack tester)

- Verify print colour in a light chamber

- Determine resistance to light

- Determine delamination forces (according to PN-88 C-89099)

- Determine tensile strength and elongation at break (according to DIN EN ISO 527)

- Determine friction forces (according to DIN EN ISO 8295)

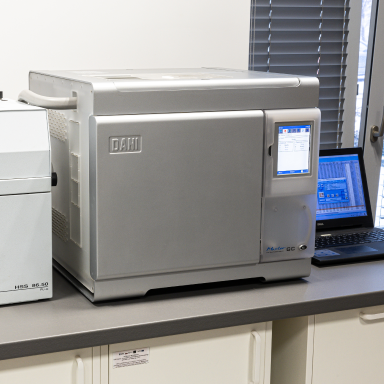

- Determine residual VOCs in films, laminates and end products (gas chromatography)

- Verify the legibility of the DIGIMARK code generated in the pattern graphics

- Simulate sterilisation and pasteurisation processes (autoclave, water bath)

- Digitally control print quality and compliance with the proof (Proofiler Eye C)

The activities of our R&D Centre

The Centre carries out research into new packaging structures and the possibility of modifying materials currently available on the market, as well as research into the physical and chemical properties of various packaging solutions. The research is carried out in cooperation with the scientific and business sector.

The main lines of action include:

Designing mono-material packaging with barrier properties, subjected to thermal processing (pasteurization or sterilization)

Development and modification of flexographic and rotogravure printing techniques towards “ProNATURA” solutions.

Development of new “SmartPAK” packaging solutions containing an interactive indicator of the contents of the packaging, ensured by means of surface printing technology.

Development of “ProACTIVE” packaging solutions, which improve selected parameters during transport and storage, guaranteeing the high quality of the packaged products and, in the case of foods, extending their shelf life.

Development of innovative composite “EkoPAK” materials, based on the guidelines and assumptions of the circular economy and bioeconomy for use in various industries, including the packaging industry.

Some of the international projects which we participate in focus on the practical use of raw materials of natural origin, which become completely decomposed once they have fulfilled their function. In addition to research and development works, we also carry out projects aimed at reducing the negative impact of packaging on the environment by increasing mono-material solutions, reducing the amount of materials used, as well as developing new ways of waste management in the packaging industry.

We are also a member of scientific and industrial associations and clusters

KB Folie Polska Sp. z o.o. is a partner of international project consortiums funded by the European Union programs HORIZON 2020, HORIZON EUROPE, and CORNET Initiative

Projekt BeFORE

“Influence of processing on innovative recyclable high-barrier materials for plastic and paper packaging”

The main objective of the BeFORE project is to improve the packaging design process for recycling and to analyse the potential of implementing innovative flexible packaging materials with alternative barriers in industrial conditions. Project is co-funded by the National Centre for Research and Development of Poland.

“Metrology for food safety in the circular economy: targeted and screening methods for contaminants in food and recycled packaging”

Project ScreenFood has received funding from the European Partnership on Metrology, co-financed from the European Union’s Horizon Europe Research and Innovation Programme and by the Participating States. Project Number: 23IND13.

GREEN-MAP

„Novel green polymeric materials for medical packaging and disposables to improve hospital sustainability”

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 872152.